Correct cutting and fitting of the Mayer PEX system is essential to achieve water tight joints. The techniques of both crimp and slide are tried and tested with both being used in the NZ market and around the world for over 30 years. By following simple guidelines and using approved tools, Mayer PEX pipe systems are rapidly implemented, deliver leak free performance and will stand the test of time.

GUIDELINES, TOOL USE & PREPARATION

Crimp Connection Method

1

Cut Pipe

The pipe should be cut square and any debris removed prior to installation.

NEVER USE A HACKSAW TO CUT PEX-a PIPE.

2

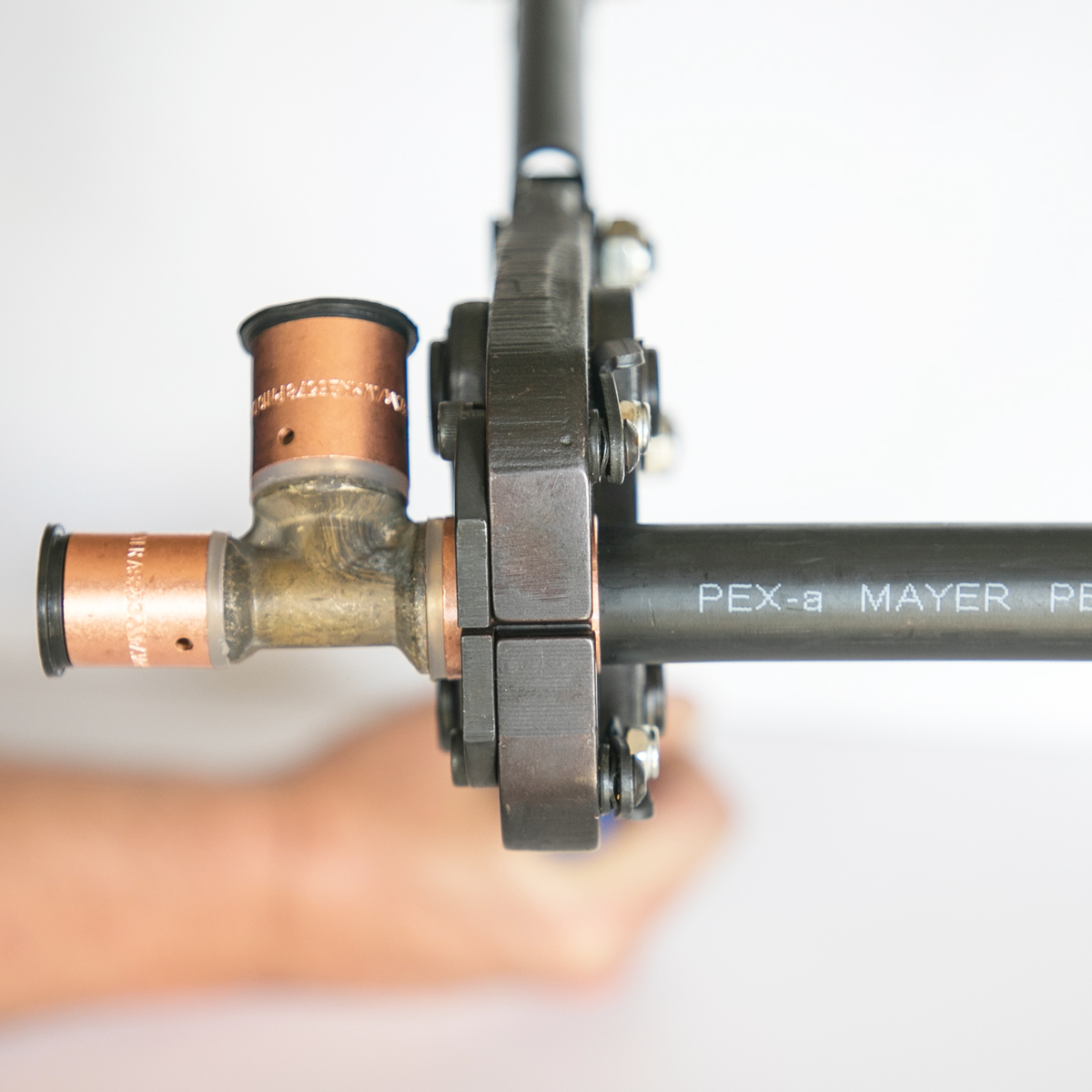

Insert Fitting

Insert the barb of the fitting into the bore of the pipe. When the pipe is inserted to the correct depth and resting against the pipe stop, the pipe will be fully visible via the inspection ports in the base plate.

3

Crimp the Fitting

Fully close the tongs of the tool and then release.

4

Gauge the Joint

Double-check the integrity of the joint by ensuring the crimp gauge can pass over the diameter of the newly formed indentations in the crimp-ring.

Slide Connection Method

1

Cut pipe at right angle

2

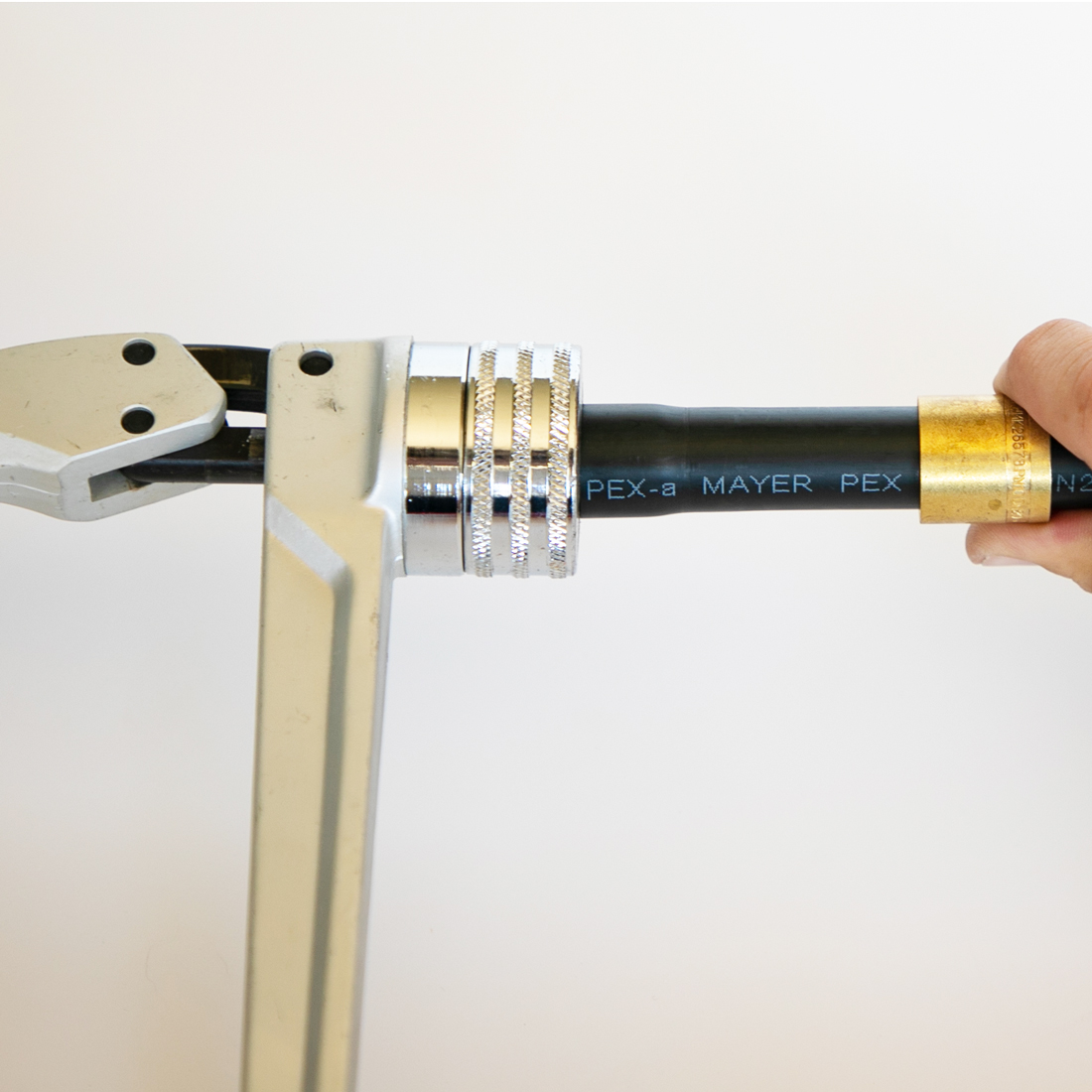

Slide on brass sleeve with chamber facing toward fitting

3

Expand pipe

4

Open expander, rotate 30° and re-expand

5

Ensure fitting is inserted

6

Press sleeve fully closed to fitting shoulder into shoulder drop